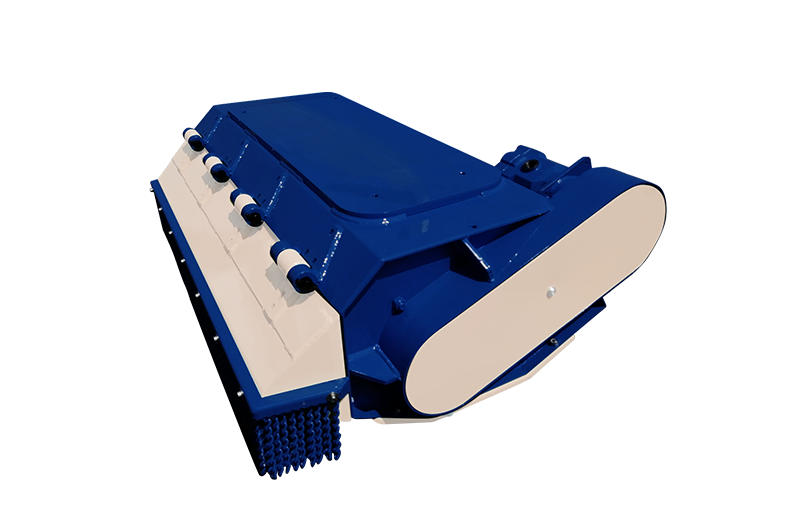

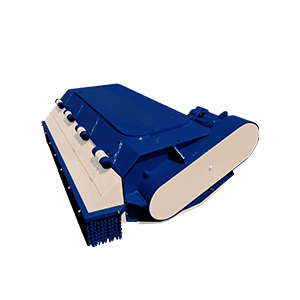

GRINDING HEAD GrindK

Very Important Product

The high-performance bushings and steel rotor brackets ensure the grinder has a longer service life and constant cutting ability.

The decision to use solely cast iron motors ensure the Klac grinder provides maximum performance even after intensive use of the tool (oil temperature rise).

The roller-feeler and the two-directional motor enable you to work without interruption, even if the material becomes clogged. (VIP)

More information

- All-steel structure

- Direct-drive motor (STANDARD)

- Two-directional rotor rotation SKF high-performance bearings

- Pressure relief valve

- Motor with internal drainage

- Flow / pressure control valve

GRINDING HEAD GrindK

TECHNICAL FEATURES

Focus on

VIP Version

- In addition to guaranteeing constant power, the belt drive and toothed pulley allow rotor rotations to be increased with the same flow rate and the same pressure.

- The twisted protective chains provide excellent anti-ejection protection

- Hinged cover

- Two-directional flail hammers

STANDARD Version

- Direct drive rotor

- Front and rear protection with rubber flaps

- Fixed cover with bolted plates

- Single-blade flail hammers

THE RANGE GRINDK grinding head

| Weight (kg) | Width (mm) | Roller feeler (⌀mm) | Rotor tube (⌀mm) | N° Knives | N° Flail hammers | Oil flow rate (L / mm) | Max pressure (bar) | |

|---|---|---|---|---|---|---|---|---|

| Model C / 0 Light 1,5 – 2t | 80 | 600 | 100 | 80 | 30 | nd | 20/25 | 150/180 |

| Model C / 0 1,5 – 2t | 100 | 800 | 100 | 80 | 40 | nd | 25/30 | 150/180 |

| Model D / 1 2 – 3,5t | 156 | 800 | 140 | 100 | 32 | 16 | 30/35 | 195/205 |

| Model E / 2 3 – 5t | 195 | 1 000 | 140 | 100 | 48 | 24 | 35/60 | 215/225 |

| Model F / 3 6 – 10t | 235 | 1 200 | 140 | 100 | 60 | 30 | 60/90 | 250/280 |

| Model G 10 – 17t | 270 | 1 200 | 140 | 100 | 60 | 30 | 60/90 | 250/280 |

For C and D models, the connections are 1/2 gas with an internal Ø of 13mm.

For models E, F and G, the connections are 3/4 gas with an internal Ø of 19mm.

OUR EQUIPMENT IN PICTURES

Documents

Brochure UK

SAFETY QUESTION

Each grinder is controlled for vibrations during the work phase to reduce the stress on the machine arm.

The plate can be mounted in the right/ left/centre position, depending on the machine and the work to be done.

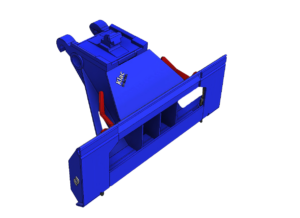

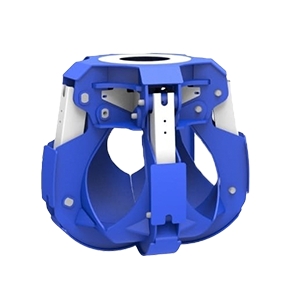

Mechanical coupler KLAC SYSTEM

Mechanical coupler KLAC SYSTEM HYDRAULIC KLAC SYSTEM

HYDRAULIC KLAC SYSTEM MECHANICAL COUPLER ALTERNATIK

MECHANICAL COUPLER ALTERNATIK Hydraulic and mechanical coupler KLAC +

Hydraulic and mechanical coupler KLAC + ROTATING HITCH ROTOK

ROTATING HITCH ROTOK TILTABLE HITCH TILTK

TILTABLE HITCH TILTK TILTABLE AND ROTATING HITCH

TILTABLE AND ROTATING HITCH DEMOLITION CLAMP

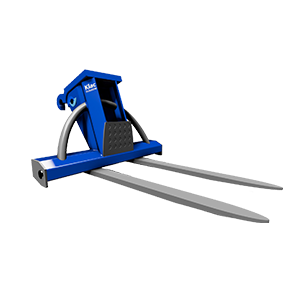

DEMOLITION CLAMP FORK PALLET LIFT

FORK PALLET LIFT SELECTION CLAMP

SELECTION CLAMP SKID ADAPTER

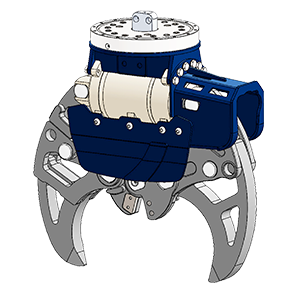

SKID ADAPTER HANDLING GRAPPLE

HANDLING GRAPPLE NARROW BUCKET SOLO

NARROW BUCKET SOLO NARROW BUCKET Duo

NARROW BUCKET Duo NARROW BUCKET Trio

NARROW BUCKET Trio GRINDING HEAD

GRINDING HEAD HEDGE TRIMMER

HEDGE TRIMMER KLAC CITY BUCKET

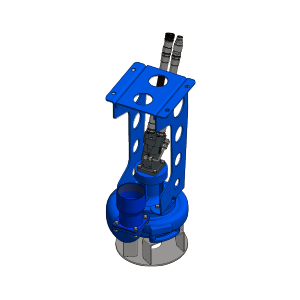

KLAC CITY BUCKET HYDRAULIC PUMP

HYDRAULIC PUMP LOG SPLITTER CLAMP

LOG SPLITTER CLAMP WOOD CLAMP

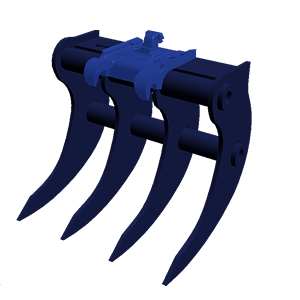

WOOD CLAMP RIPPER TOOTH

RIPPER TOOTH MULTIRIPPER BUCKET

MULTIRIPPER BUCKET KLAC MANIP

KLAC MANIP